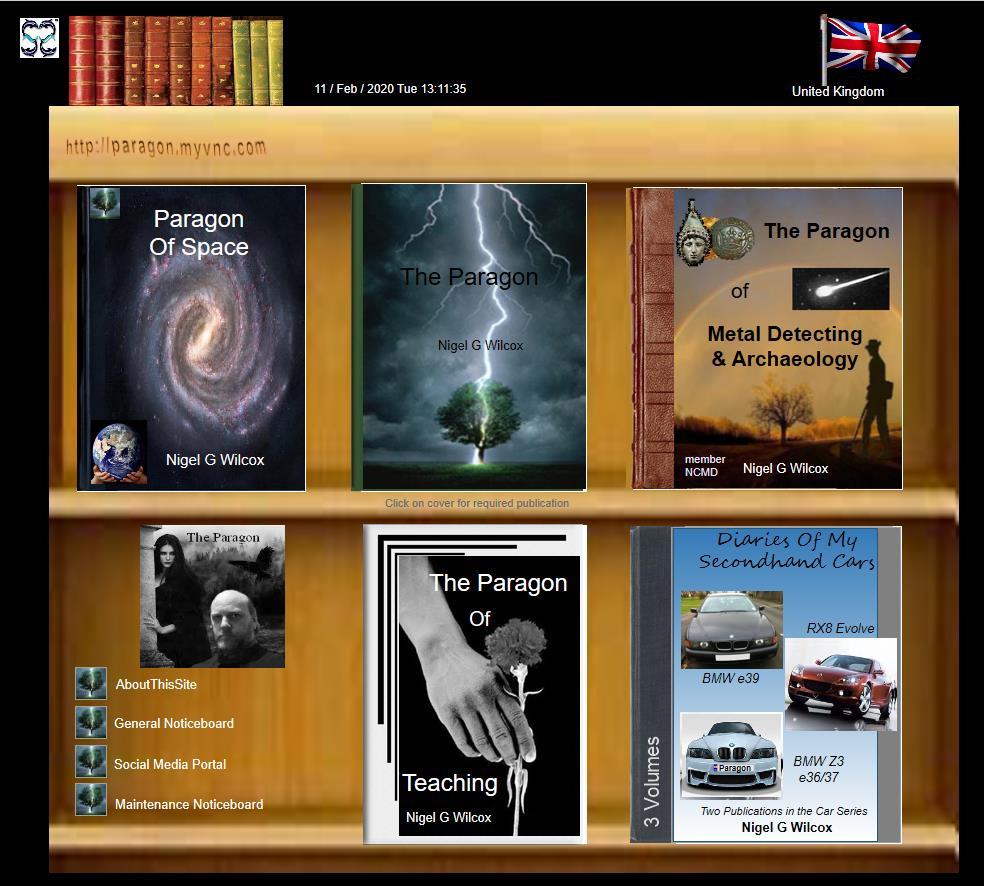

Looking After Your Finds - Reference

A Short History of Metals

Powered By Sispro1

A Short History of Metals

Process Metallurgy is one of the oldest applied sciences Its history can be traced back to 6000 BC. Admittedly, its form at that time was rudimentary, but, to gain a perspective in Process Metallurgy, it is worthwhile to spend a little time studying the initiation of mankind's association with metals. Currently there are 86 known metals. Before the 19th century only 24 of these metals had been discovered and, of these 24 metals, 12 were discovered in the 18th century. Therefore, from the discovery of the first metals - gold and copper until the end of the 17th century, some 7700 years, only 12 metals were known. Four of these metals, arsenic, antimony , zinc and bismuth , were discovered in the thirteenth and fourteenth centuries, while platinum was discovered in the 16th century. The other seven metals, known as the Metals of Antiquity, were the metals upon which civilisation was based. These seven metals were:

(1) Gold (ca) 6000BC

(2) Copper,(ca) 4200BC

(3) Silver,(ca) 4000BC

(4) Lead, (ca) 3500BC

(5) Tin, (ca) 1750BC

(6) Iron,smelted, (ca) 1500BC

(7) Mercury, (ca) 750BC

These metals were known to the Mesopotamians, Egyptians, Greeks and the Romans. Of the seven metals, five can be found in their native states, e.g., gold, silver, copper, iron (from meteors) and mercury. However, the occurrence of these metals was not abundant and the first two metals to be used widely were gold and copper. And, of course, the history of metals is closely linked to that of coins and gemstones.

Gold

Gold articles are found extensively in antiquity mainly as jewellery e.g. Bracelets, rings etc. Early gold artifacts are rarely pure and most contain significant silver contents. This led to the ancients naming another metal - electrum, which was an alloy of gold and silver, pale yellow and similar in color to amber. Therefore, early gold varied from pure through electrum to white gold. The symbol for gold is Au from the latin aurum meaning shining dawn.

Stone age man learned to fashion gold into jewelry and ornaments, learning that it could be formed into sheets and wires easily. However, its malleability, which allows it to be formed into very thin sheet (0.000005 inches), ensures that it has no utilitarian value and early uses were only decorative. As gold is a noble metal, being virtually noncorrosive and tarnish free, it served this purpose admirably.

Gold is widely dispersed through the earth's crust and is found in two types of deposits : lode deposits, which are found in solid rock and are mined using conventional mining techniques, and placer deposits which are gravelly deposits found in stream beds and are the products of eroding lode deposits. Since gold is found uncombined in nature, early goldsmiths would collect small nuggets of gold from stream beds etc., and then weld them together by hammering.

Thus we find the first problem in process metallurgy : The metal deposit must be identified. In the case of the first metals color was the most important factor as it allowed the metal to be recognized in surrounding rock, stones, gravel and dirt (gangue) and separated. Clearly, after recognition, separation is next problem followed by concentration. These three steps are very important and the economics of these steps usually define whether it is viable to produce the metal from a set deposit. In the early days all three steps were carried out simultaneously. Gold is widely dispersed throughout the earths crust (0.005 ppm) at a very small level, therefore, it is very important to find naturally occurring concentrations. The scarcity of gold and its value, due to mankinds fascination with its color, have lead to gold being the one of the more important metals in daily life.

Copper

The use of copper in antiquity is of more significance than gold as the first tools, implements and weapons were made from copper. From 4,000 to 6,000 BC was the Chalcolithic period which was when copper came into common use. The symbol for copper is Cu and comes from the latin cuprum meaning from the island of Cyprus. Initially copper was chipped into small pieces from the main mass. The small pieces were hammered and ground in a manner similar to the techniques used for bones and stones. However, when copper was hammered it became brittle and would easily break. The solution to this problem was to anneal the copper. This discovery was probably made when pieces were dropped in camp fires and then hammered. By 5,000 BC copper sheet was being made.

By 3600 BC the first copper smelted artifacts were found in the Nile valley and copper rings, bracelets, chisels were found. By 3000 BC weapons, tools etc. were widely found. Tools and weapons of utilitarian value were now within society, however, only kings and royalty had such tools; it would take another 500 years before they reached the peasants.

Malachite, a green friable stone, was the source of copper in the early smelters. Originally it was thought that the smelting of copper was by chance dropping of malachite into campfires. However, campfire temperatures are normally in the region of 600-650 C, whereas, 700-800 C is necessary for reduction. It is more probable that early copper smelting was discovered by ancient potters whose clay firing furnaces could reach temperatures of 1100-1200 C. If Malachite was added to these furnaces copper nodules would easily be found. Although the first smelted copper was found in the Nile valley, it is thought that this copper was brought to Egypt by the Gerzeans and copper smelting was produced first in Western Asia between 4000 and 4300 BC.

Although copper can be found free in nature the most important sources are the minerals cuprite, malachite, azurite, chalcopyrite and bornite. Copper is reddish colored, malleable, ductile and a good conductor of heat and electricity. Approximately 90% 0f the worlds primary copper originates in sulfide ores.

Lead

Lead is not found free in nature but Galena (lead sulfide) was used as an eye paint by the ancient Egyptians. Galena has a very metallic looking appearance and was, therefore, likely to attract the attention of early metalworkers. The production of metallic lead from its ore is relatively easy and could have been produced by reduction of Galena in a camp fire. The melting point of lead is 327 C, therefore, it would easily flow to the lowest point in the fireplace and collect. At first lead was not used widely because it was too ductile and the first uses of lead were around 3500 B.C.. Lead's use as a container and conduit was important and lead pipes bearing the insignia of Roman emperors can still be found. Lead is highly malleable, ductile and noncorrosive making it an excellent piping material. Its symbol is Pb from the latin plumbum.

The ability of lead to flow and collect at the bottom of the campfire is an important concept in process metallurgy as reduction reactions to be useful must cause a phase separation between the metal and the gangue. Also, the phase separation should also enable the metal to be cast into a desired shape once concentrated.

Silver

Although silver was found freely in nature, its occurrence was rare. Silver is the most chemically active of the noble metals, is harder than gold but softer than copper. It ranks second in ductility and malleability to gold. It is normally stable in pure air and water but tarnishes when exposed to ozone, hydrogen sulfide or sulfur. Due to its softness, pure silver was used for ornaments, jewelry and as a measure of wealth. In a manner similar to gold, native silver can easily be formed. Silver's symbol is Ag from the latin argentum.

Galena always contains a small amount of silver and it was found that if the lead was oxidized into a powdery ash a droplet of silver was left behind. Another development in this process was the discovery that if bone ash was added to the lead oxide, the lead oxide would be adsorbed and a large amount of material could be processed. By 2500 BC the cupellation process was the normal mode of silver manufacture.

(1) Gold (ca) 6000BC

(2) Copper,(ca) 4200BC

(3) Silver,(ca) 4000BC

(4) Lead, (ca) 3500BC

(5) Tin, (ca) 1750BC

(6) Iron,smelted, (ca) 1500BC

(7) Mercury, (ca) 750BC

These metals were known to the Mesopotamians, Egyptians, Greeks and the Romans. Of the seven metals, five can be found in their native states, e.g., gold, silver, copper, iron (from meteors) and mercury. However, the occurrence of these metals was not abundant and the first two metals to be used widely were gold and copper. And, of course, the history of metals is closely linked to that of coins and gemstones.

Gold

Gold articles are found extensively in antiquity mainly as jewellery e.g. Bracelets, rings etc. Early gold artifacts are rarely pure and most contain significant silver contents. This led to the ancients naming another metal - electrum, which was an alloy of gold and silver, pale yellow and similar in color to amber. Therefore, early gold varied from pure through electrum to white gold. The symbol for gold is Au from the latin aurum meaning shining dawn.

Stone age man learned to fashion gold into jewelry and ornaments, learning that it could be formed into sheets and wires easily. However, its malleability, which allows it to be formed into very thin sheet (0.000005 inches), ensures that it has no utilitarian value and early uses were only decorative. As gold is a noble metal, being virtually noncorrosive and tarnish free, it served this purpose admirably.

Gold is widely dispersed through the earth's crust and is found in two types of deposits : lode deposits, which are found in solid rock and are mined using conventional mining techniques, and placer deposits which are gravelly deposits found in stream beds and are the products of eroding lode deposits. Since gold is found uncombined in nature, early goldsmiths would collect small nuggets of gold from stream beds etc., and then weld them together by hammering.

Thus we find the first problem in process metallurgy : The metal deposit must be identified. In the case of the first metals color was the most important factor as it allowed the metal to be recognized in surrounding rock, stones, gravel and dirt (gangue) and separated. Clearly, after recognition, separation is next problem followed by concentration. These three steps are very important and the economics of these steps usually define whether it is viable to produce the metal from a set deposit. In the early days all three steps were carried out simultaneously. Gold is widely dispersed throughout the earths crust (0.005 ppm) at a very small level, therefore, it is very important to find naturally occurring concentrations. The scarcity of gold and its value, due to mankinds fascination with its color, have lead to gold being the one of the more important metals in daily life.

Copper

The use of copper in antiquity is of more significance than gold as the first tools, implements and weapons were made from copper. From 4,000 to 6,000 BC was the Chalcolithic period which was when copper came into common use. The symbol for copper is Cu and comes from the latin cuprum meaning from the island of Cyprus. Initially copper was chipped into small pieces from the main mass. The small pieces were hammered and ground in a manner similar to the techniques used for bones and stones. However, when copper was hammered it became brittle and would easily break. The solution to this problem was to anneal the copper. This discovery was probably made when pieces were dropped in camp fires and then hammered. By 5,000 BC copper sheet was being made.

By 3600 BC the first copper smelted artifacts were found in the Nile valley and copper rings, bracelets, chisels were found. By 3000 BC weapons, tools etc. were widely found. Tools and weapons of utilitarian value were now within society, however, only kings and royalty had such tools; it would take another 500 years before they reached the peasants.

Malachite, a green friable stone, was the source of copper in the early smelters. Originally it was thought that the smelting of copper was by chance dropping of malachite into campfires. However, campfire temperatures are normally in the region of 600-650 C, whereas, 700-800 C is necessary for reduction. It is more probable that early copper smelting was discovered by ancient potters whose clay firing furnaces could reach temperatures of 1100-1200 C. If Malachite was added to these furnaces copper nodules would easily be found. Although the first smelted copper was found in the Nile valley, it is thought that this copper was brought to Egypt by the Gerzeans and copper smelting was produced first in Western Asia between 4000 and 4300 BC.

Although copper can be found free in nature the most important sources are the minerals cuprite, malachite, azurite, chalcopyrite and bornite. Copper is reddish colored, malleable, ductile and a good conductor of heat and electricity. Approximately 90% 0f the worlds primary copper originates in sulfide ores.

Lead

Lead is not found free in nature but Galena (lead sulfide) was used as an eye paint by the ancient Egyptians. Galena has a very metallic looking appearance and was, therefore, likely to attract the attention of early metalworkers. The production of metallic lead from its ore is relatively easy and could have been produced by reduction of Galena in a camp fire. The melting point of lead is 327 C, therefore, it would easily flow to the lowest point in the fireplace and collect. At first lead was not used widely because it was too ductile and the first uses of lead were around 3500 B.C.. Lead's use as a container and conduit was important and lead pipes bearing the insignia of Roman emperors can still be found. Lead is highly malleable, ductile and noncorrosive making it an excellent piping material. Its symbol is Pb from the latin plumbum.

The ability of lead to flow and collect at the bottom of the campfire is an important concept in process metallurgy as reduction reactions to be useful must cause a phase separation between the metal and the gangue. Also, the phase separation should also enable the metal to be cast into a desired shape once concentrated.

Silver

Although silver was found freely in nature, its occurrence was rare. Silver is the most chemically active of the noble metals, is harder than gold but softer than copper. It ranks second in ductility and malleability to gold. It is normally stable in pure air and water but tarnishes when exposed to ozone, hydrogen sulfide or sulfur. Due to its softness, pure silver was used for ornaments, jewelry and as a measure of wealth. In a manner similar to gold, native silver can easily be formed. Silver's symbol is Ag from the latin argentum.

Galena always contains a small amount of silver and it was found that if the lead was oxidized into a powdery ash a droplet of silver was left behind. Another development in this process was the discovery that if bone ash was added to the lead oxide, the lead oxide would be adsorbed and a large amount of material could be processed. By 2500 BC the cupellation process was the normal mode of silver manufacture.

[1-3]

Copyright All Rights Reserved by Nigel G Wilcox E-Mail: ngwilcox100@gmail.com

Metals

Group Pages

Complimentary Topics

Designed by Nigel G Wilcox

The Paragon Of Metal Detecting

& Archaeology

& Archaeology

Who Owns the World's Gold?

Pages

Member NCMD

Reference Menu